Image Source: Google

In the world of manufacturing and design, precision and efficiency are key. One technology that has revolutionized the way materials like polymer are cut is laser cutting. Polymer laser cutting involves the use of a high-powered laser to precisely cut through polymer materials with remarkable accuracy and speed. Let's delve into the magic of polymer laser cutting and how it transforms concepts into reality.

The Process of Polymer Laser Cutting

Step 1: Designing the Concept

- The first step in the process of polymer laser cutting is to create a design concept. This involves determining the dimensions, shapes, and intricate details of the desired cut. If you are looking for polymer laser cutting then, you may check this website.

- Design software such as AutoCAD or Adobe Illustrator is commonly used to create the digital design that will guide the laser cutting machine.

Step 2: Material Selection

- Choosing the right polymer material is crucial for the success of the laser cutting process. Different polymers have varying properties such as flexibility, heat resistance, and transparency.

- The material selected should be compatible with laser cutting and produce clean cuts without melting or warping.

Step 3: Setting Up the Laser Cutting Machine

- Once the design and material are finalized, the next step is to set up the laser cutting machine. This involves calibrating the laser power, speed, and focus to ensure precise and clean cuts.

- Operators must also consider factors such as the thickness of the material and the intricacy of the design when setting up the machine.

The Magic of Polymer Laser Cutting

Precision and Accuracy

- One of the most remarkable aspects of polymer laser cutting is its precision and accuracy. The high-powered laser can cut through polymer materials with a tolerance of mere microns, ensuring that the final product is exactly as designed.

- This level of precision allows for the creation of intricate and complex designs that would be difficult to achieve using traditional cutting methods.

Speed and Efficiency

- Laser cutting is incredibly fast and efficient compared to traditional cutting methods. The laser can move quickly across the material, cutting with precision in a fraction of the time it would take using a manual process.

- This speed and efficiency make polymer laser cutting ideal for mass production of parts and components, saving time and costs for manufacturers.

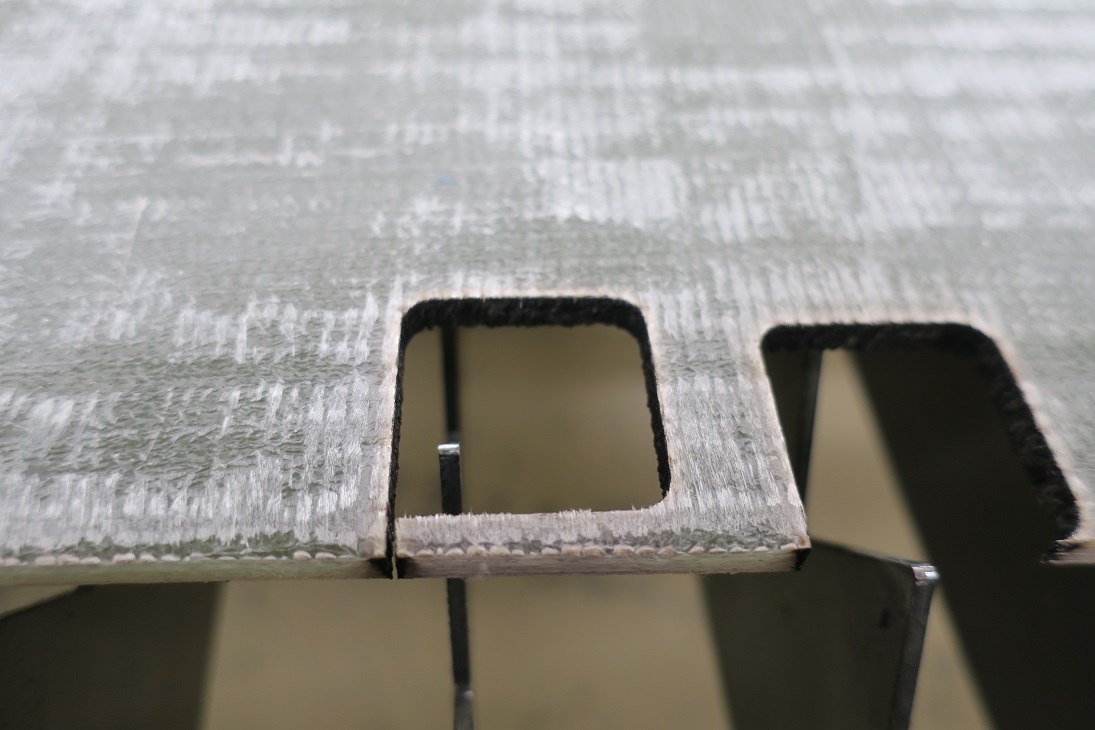

Clean and Smooth Cuts

- Unlike traditional cutting methods that can leave rough edges or require post-processing to smooth out, polymer laser cutting produces clean and smooth cuts without the need for additional finishing.

- The laser melts the polymer material along the cutting path, resulting in precise edges that require minimal to no further refinement.

Applications of Polymer Laser Cutting

Prototyping and Product Development

- One of the primary applications of polymer laser cutting is in prototyping and product development. Designers and engineers can quickly create prototypes and iterate on designs with high precision and speed using laser cutting technology.

- This enables rapid product development and testing, allowing companies to bring new products to market faster.

Customization and Personalization

- Polymer laser cutting is also widely used for customization and personalization of products. Whether it's engraving logos, cutting intricate patterns, or creating unique shapes, laser cutting offers endless possibilities for customization.

- From custom signage to personalized gifts, polymer laser cutting allows for the creation of bespoke products tailored to individual preferences.

Industrial Manufacturing

- In the industrial manufacturing sector, polymer laser cutting is utilized for mass production of components and parts. The speed, precision, and efficiency of laser cutting make it a preferred method for producing consistent and high-quality products at scale.

- Industries such as automotive, aerospace, and electronics rely on polymer laser cutting for manufacturing a wide range of products with tight tolerances and intricate designs.

From Concept to Reality: The Magic of Polymer Laser Cutting