Image Source: Google

Screen printing is a popular method of printing designs on various materials such as t-shirts, bags, and other apparel. Top screen printing companies have mastered the art of turning concepts into reality through a meticulous process that involves creativity, precision, and cutting-edge technology. Let's take a closer look at how these companies bring ideas to life through their intricate process.

The Design Phase

Concept Development

- Top the best screen printing companies start by collaborating with clients to understand their vision and design requirements.

- Designers brainstorm ideas and concepts based on the client's brief, ensuring that the design aligns with the client's brand and goals.

- Concept sketches and digital mockups are created to visualize the final product and make any necessary revisions before moving forward.

Artwork Preparation

- Once the final design is approved, it is transferred to a digital format using graphic design software.

- The artwork is prepared for screen printing by separating colors and creating individual screens for each color layer.

- Designers pay close attention to details such as color accuracy, size, and placement to ensure the design translates perfectly onto the chosen material.

The Printing Process

Screen Preparation

- A screen mesh is coated with a light-sensitive emulsion and dried to create a stencil of the design.

- The prepared screen is then exposed to UV light with the digital artwork, hardening the emulsion where the design is, while the rest washes away, leaving the stencil on the screen.

Ink Selection and Mixing

- Top screen printing companies carefully select inks to match the desired colors of the design.

- Inks are mixed in precise quantities to achieve the exact hue and consistency needed for the printing process.

- Samples are often printed and tested to ensure color accuracy and vibrancy before full production begins.

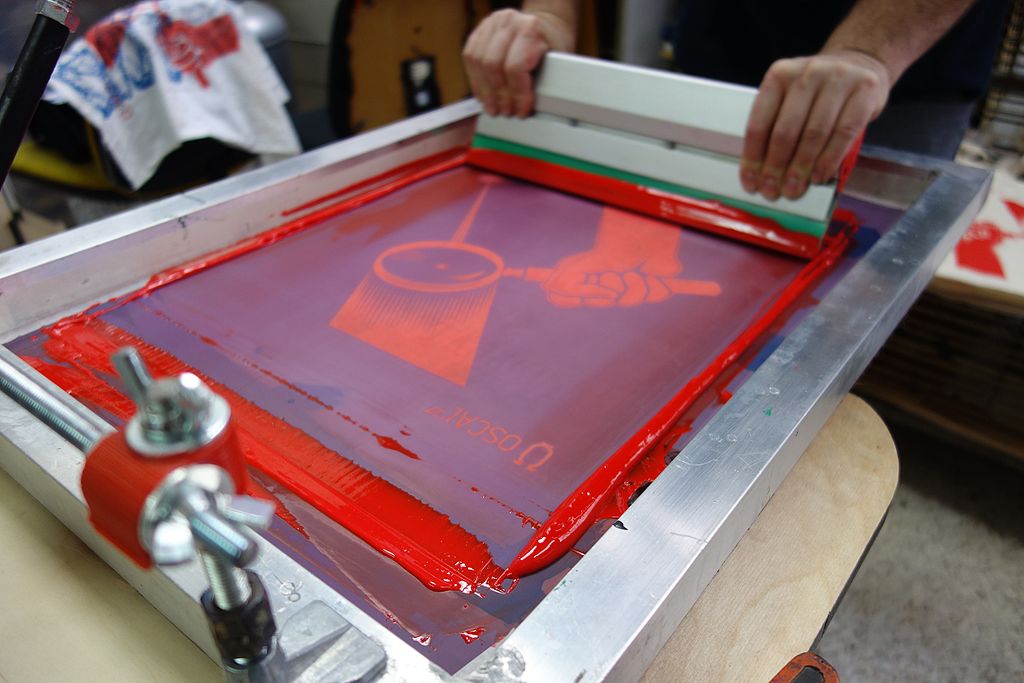

Printing

- The screen is mounted onto a printing press, and the prepared ink is loaded onto the screen.

- Each color layer is printed one at a time, with the screen lifted and lowered onto the material to transfer the ink onto the surface.

- Multiple passes may be required for complex designs with multiple colors, with each layer carefully aligned to create a cohesive final product.

Quality Control and Finishing

Inspection

- After printing is complete, each product is inspected for quality assurance.

- Any imperfections or errors are identified and corrected to ensure the final product meets the company's high standards.

Curing

- To set the ink and ensure durability, the printed material is cured at high temperatures using a conveyor dryer or heat press.

- This process bonds the ink to the fabric, making it resistant to fading, cracking, and peeling over time.

Finishing Touches

- Once the ink is cured, any additional finishing touches such as folding, tagging, or packaging are completed according to the client's specifications.

- The finished products are then ready for distribution or delivery to the client, showcasing the high-quality workmanship of the top screen printing companies.

Conclusion

Top screen printing companies excel in transforming concepts into tangible products through a meticulous process that involves creativity, precision, and state-of-the-art technology. From concept development and artwork preparation to the printing process and quality control, these companies ensure that every step is executed with utmost care and attention to detail. By mastering the art of screen printing, these companies bring ideas to life in vibrant colors and intricate designs, making them the go-to choice for clients looking for top-quality custom apparel.